As LEO satellites have constantly gained their popularity, the production value of the global satellite industry is expected to exceed USD 300 billion by 2023 at a year-on-year growth rate of 4.5%, according to a market survey. Facing this new hot market, the Institute for Information Industry especially invited the giant of certification world, DEKRA Taiwan, to co-organize an “Online Meeting of LEO Satellite Communication Earth Equipment and Specification Testing Regulations” to align with the “MOEA Industrial Bureau Pilot Program of Space Industry Supply Chain Development.” DEKRA Taiwan delivered keynote speeches on rich experience in “Regulations and Certification,” from DEKRA Testing & Certification, and remarkable capacity of “Reliability Validation” from DEKRA iST. In the meeting, both parties explored the testing specifications that suit domestic and overseas needs in order to help enhance manufacturers’ knowledge of testing capacity in LEO satellite communication earth equipment.

President Hsieh, Kuang-Cheng of Taiwan 5-based Industry Development Association was invited to moderate the meeting, and Aaron Lee, Managing Director of DEKRA Taiwan, gave his opening remarks. Managing Director Aaron Lee expressed that as people continue to pursue a safer and more convenient life, this will keep driving changes for technological development and industry applications. To be specific, the Internet of Things and advanced cloud computing even prompt all sectors to increasingly secure high-speed bandwidth at low cost. On the supply aspect, LEO has various advantages, such as multifunction, low-cost, advanced machinery structure, easy to assembly and launch, suitable for large-volume production and shorter life cycle, which makes it favored by the market. It is estimated that the market scale will grow from USD 9.6 billion in 2021 to USD 19.8 billion by 2026, with a CAGR up to 15.5%.

Aaron Lee, Managing Director of DEKRA Taiwan further added that the multiple functions of LEO satellites, including remote sensing, earth observation, and communication applications in particular, will usher us into the LEO satellite market in the next five years. When entering the space industry chain, it is imperative that players put greater emphasis on product safety and reliability. Various kinds of tests need to be performed for specification compliance with an aim to overcoming challenges of low-frequency vibration, dramatic temperature difference, and electromagnetic and radiated interference. DEKRA Taiwan has been equipped with considerable validation experience and sufficient testing capacity, so it can support Taiwanese businesses to go through the trials together before they can make it to the space.

James Lee, EMC & RF Senior Legal Manager of DEKRA Testing & Certification shared some information about LEO satellite related regulations and certification

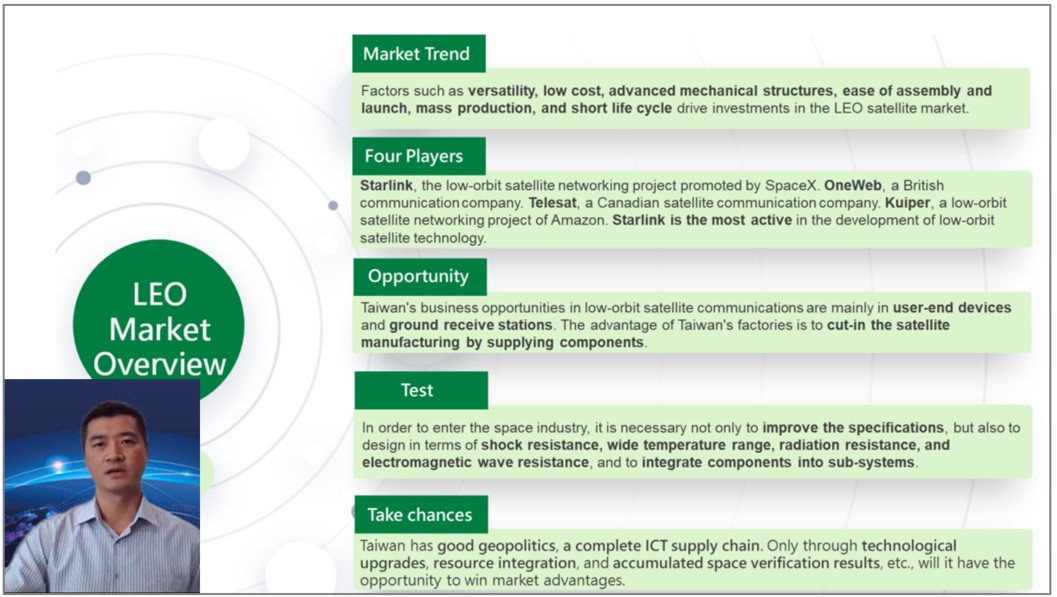

James Lee, EMC & RF Senior Legal Manager of DEKRA Testing & Certification, expanded the topic on “LEO satellite related regulations and certification.” He pointed out that the development of satellite communication has opened up the prelude of competition because of the Starlink project and reforms on rockets that can be vertically recycled with a reusable launch system. Therefore, there will be satellites running at low-Earth orbit outside of the Starlink project.

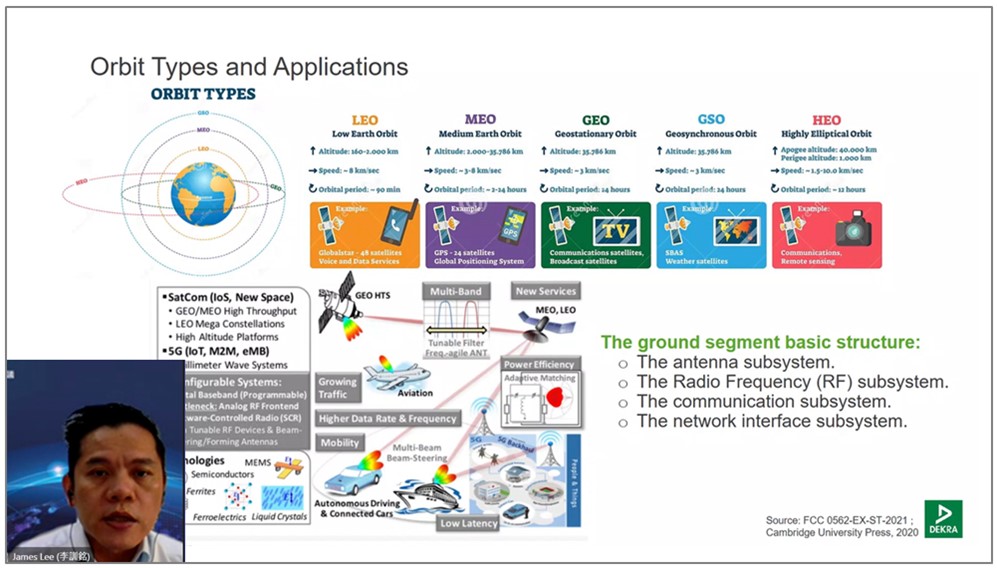

James Lee emphasized that at the time of 5G 3GPP release 15, the potentiality of combing the operation of satellite communication and 5G NR was under discussion. For release 17 and 18, it can be seen that satellite communication is an essential partner for 5G NR and 5G IoT in the future. This is why the development and research and certification of earth equipment, namely Gateway, User Terminal, Indoor/Outdoor WiFi Router and C-V2X, are also extremely important. Many countries are speeding up to define the testing regulations governing usage of spectrum. For example, the United States embarked on the development of satellites and earth stations when NASA was founded in 1958, followed by the operation of commercial satellites. FCC Part 25 is the regulation and guideline for the industry to conduct certification tests and apply for FCC for their satellite communication equipment. ETSI categorizes the SES (satellite earth station and system) testing regulations based on the frequency used, the type of the earth station system, and the way it is used.

EN 303 981 included in the issues for discussion this time focuses on NGSO bandwidth earth station, while EN 302 977 is used for vehicle-mounted earth station. ETSI has based the regulations and testing on satellites’ characteristics, such as TX/RX, performance, and function so as to avoid impact on satellites or user ends as much as possible. To carry out testing of satellite earth stations, this is something that a lab needs to preemptively deploy while offering testing services.

As a world-class testing and certification body, DEKRA provides one-stop, integrated solutions to testing, certification, and training at testing labs across Europe, North America, and Asia-Pacific regions. The company is well served with EMC, RF, 5G, V2X, electrification safety, functional safety, and reliability verification. DEKRA iST has become the best partner for you to develop satellite communication by assisting Taiwanese operators with the certification of LEO satellites and taking further steps to international certification.

General Lee, Director of DEKRA iST, introduced the capacity of aerospace field for LEO satellites and shared his experiences.

Director General Lee gave an overview about DEKRA iST’s testing experiences in the aerospace sector. For instance, since 2020, the company has participated in the advanced rocket project by the National Yang Ming Chiao Tung University for vibration and shock tests. A large vibration test facility is applied to simulate the environment where a rocket is about to be launched to ensure the reliability level of the parts and components. This simulation test can significantly reduce the probability of launch failure due to reliability issues of the parts of components when the rocket really goes up. Starting from 2021, DEKRA iST also officially became validation partner of the Advanced Rocket Research Center (referred to as ARRC).

General Lee further explained that what matters to a reliability test is adopting different environmental stress to verify both the operational and non-operational level of product design, or testing to failure. In addition to the level of product design, the method to test reliability can also determine a product's life time (or mean time between failure, MTBF) that involves prediction, demonstration and field return of the lifetime of reliability. The result of a reliability test can not only help developers and researchers refine the processes of product development, but also discover any design defects beforehand, improving product quality and mitigating the risks of field returns.

DEKRA iST provides a series of solutions to reliability validation on LEO satellite products, along with a complete portfolio of testing capacity, including large walk-in temperature & humidity chambers, high-tonnage vibration tables (highest load up to 10 tons), drop test machines, altitude chambers, and so on. At the phase of product development, the product would undergo highly accelerated life testing (HALT), where it experiences changes in temperature and random vibration. The machine emits great power to trigger potential failure in a short period of time, which is the process of testing to failure. In the meantime, the personnel can work with failure analysis tools to swiftly clarify the causes of failure and identify the crux of issues for further improvement. Following official mass production on the way, the last mile of delivery to customers is strictly checked in line with the testing methods specified by the International Safe Transit Association (ISTA). As the most reliable validation partner, DEKRA iST devises strategies aligned with each process of development and research, mass production, and field returns through the one-stop services of reliability validation and failure analysis.

To complete our PROBLEM SOLVED mission for validation, DEKRA iST team also provides professional consultation service.

For any problem about validation, please feel free to email us. 📧sos@dekra-ist.com