Electronic products nowadays are flaunting its ruggedness; therefore, the quality requirements at commercial or industrial level are not deemed sufficient to demonstrate their high reliability as a strength. In an era where technology has hugely advanced, it is not difficult to create electronics that can be used in all kinds of environments, be it a desert of high temperature, a tundra below 0°C on average, or a rainforest with high precipitation. Under such complex environments, unlike commercial or industrial standard, a military standard emphasizes tailoring an equipment's environmental design and test limits to the conditions to verify its reliability. Brands that develop information and communication lineups and associated offerings start to apply military standards to the consumption market in the hope of highlighting the high level of durability and reliability of their own products.

The test criteria of the United States Military Standard, MIL-STD-810, covers a broad range of complex environments, including low pressure for altitude testing, exposure to high and low temperature, thermal shock, solar radiation, rain, humidity, fungus, salt fog, sand and dust exposure, explosive atmosphere, centrifugal force, vibration, shock, acid environment, and frozenness. The standard lists the test criteria as the reference of using military equipment in all possible environmental conditions.

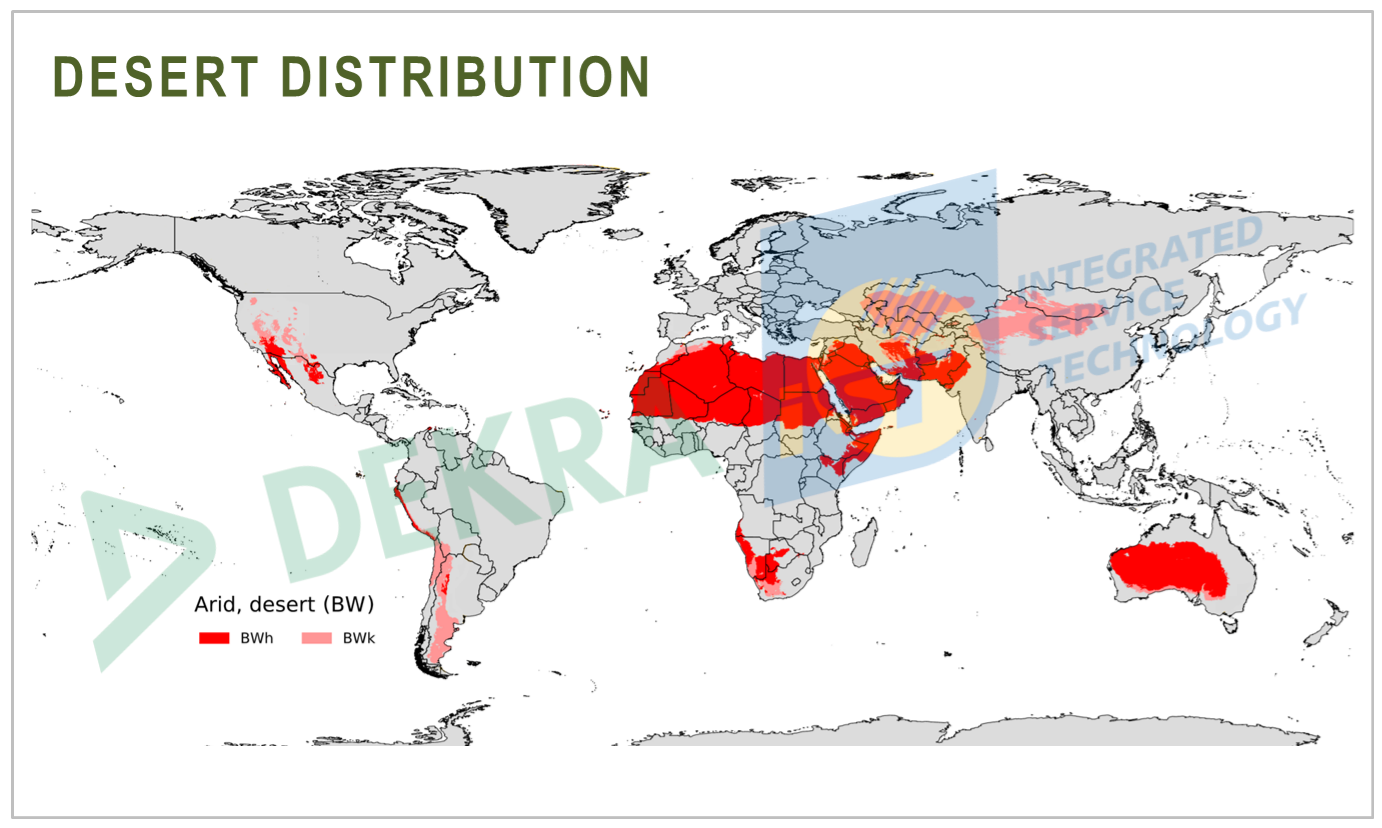

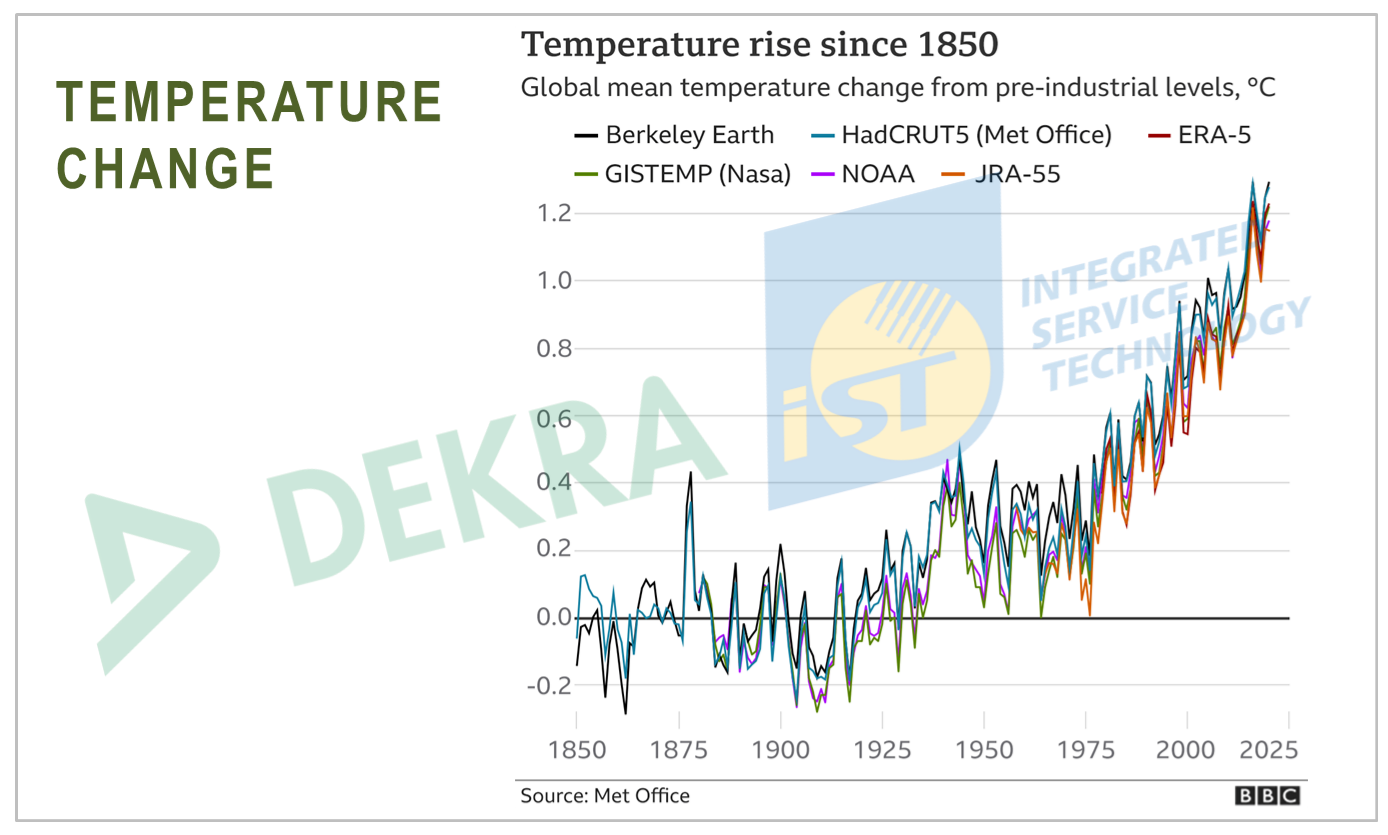

The quality and service life of a product is heavily influenced by the environmental conditions that it has been exposed to. In particular, the resistance of a product to the harsh climate from the extreme climate areas should definitely be examined. Several desert areas are scattered around the world. The particle sizes of the sand in each desert area are distinct. The sand and dust may obstruct the openings of a product or penetrate cracks, bearings and joints, which could easily lead to a breakdown. Consequently, it is a big challenge to have electronic products to function normally in such an extreme climate. In addition, in the wake of global warming, the temperate has climbed up year by year, and the impact on the reliability of electronics has also been escalated. This is why product verification has become key to quality, while the test methods also have to reflect the results of climate change over time.

Figure 1: Global Distribution of Deserts

Reference: https://simple.wikipedia.org/wiki/Desert_climate

Reference: https://simple.wikipedia.org/wiki/Desert_climate

Figure 2: Global Mean Temperature Difference

Reference: https://www.bbc.com/zhongwen/trad/science-57749347

Reference: https://www.bbc.com/zhongwen/trad/science-57749347

DEKRA iST is centered around helping customers solve all difficulties in product validation. The engineering team observed that with rising demands for rapid product development and extreme use scenarios, the IEC 60529 sand and dust test used for general electronic products cannot fully satisfy the test requirements nowadays. On top of Procedure I, DEKRA iST introduced equipment for Procedure II (Figure 3) to perform the sand and dust testing in accordance with MIL-STD-810, leveling up their capacity at military level. This not only helps enhance the product reliability for different brands, but also boosts their market competitiveness and shortens the test period.

Figure 3: DEKRA iST's MIL-STD-810 Sand and Dust Testing Equipment (Procedure I & II)

Reference: DEKRA iST

Reference: DEKRA iST

Characteristics and Advantages of Sand and Dust Testing Procedure II of MIL-STD-810

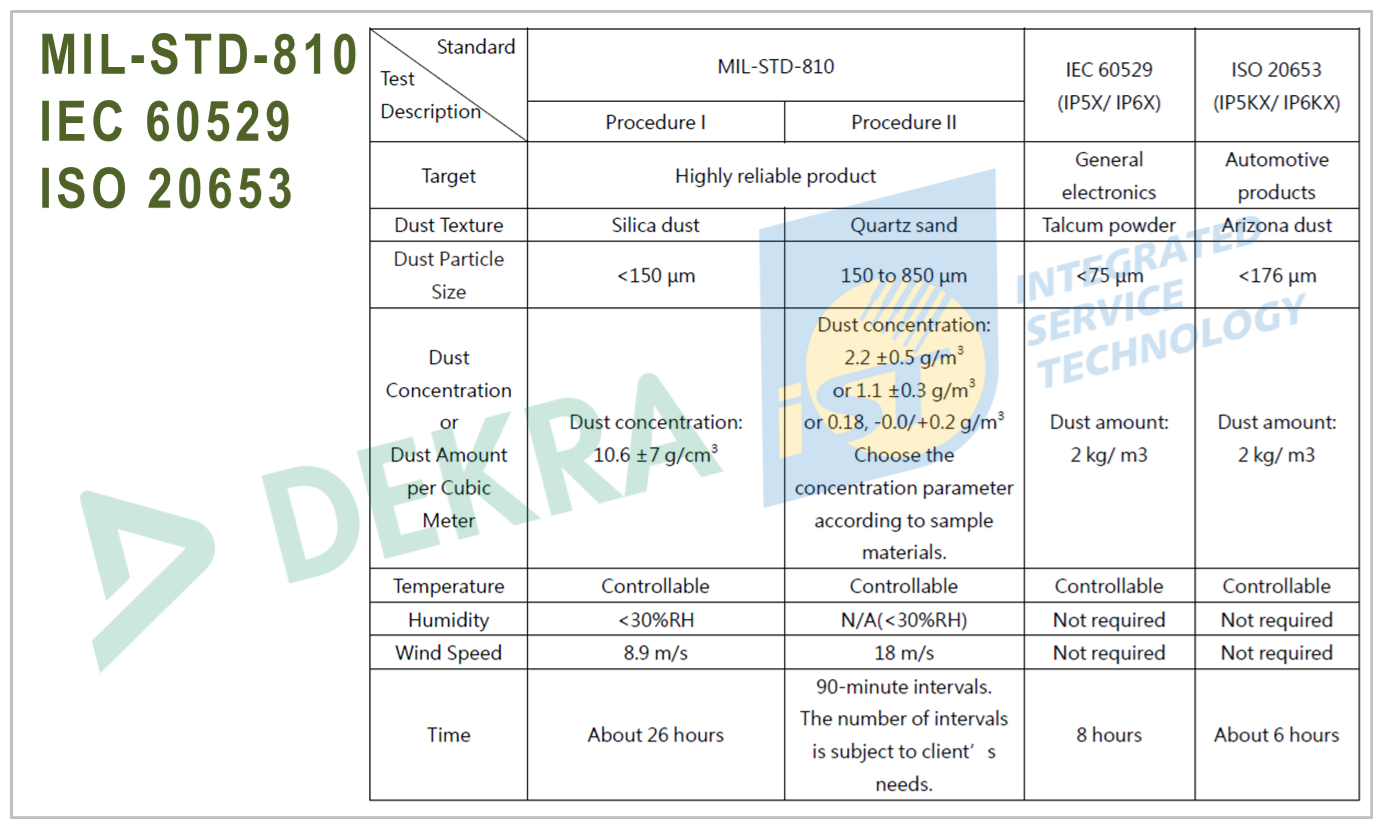

Unlike IEC 60529 used for general electronic products and ISO 20653 used for automotive products, MIL-STD-810 Procedure II is a series of tests designed by the United States Department of Defense. The performance and reliability of a product will be tested for storage and operation functionalities with larger particle sizes (150 to 850 μm) and higher wind speed (18 m/s) under high temperature environments. A detailed comparison is summarized in Figure 4:

Figure 4: Breakdown of MIL-STD-810, IEC 60529 and ISO 20653 by DEKRA iST

Reference: DEKRA iST

Reference: DEKRA iST

MIL-STD-810 Sand and Dust Testing Procedure II for Enhanced Competitiveness

In the early phase of design and verification of general electronic or automotive products, it is suggested that MIL STD 810H Method 510.7 Procedure II, along with the existing requirements of IEC 60529 and ISO 20653, be followed. The purpose is to put the products to test under high temperature, high wind speech, and large particle sizes, substantiating their reliability and increasing the competitiveness.

Precautions of MIL-STD-810 Sand and Dust Testing Procedure II

At a high temperature, it is very likely that sand and dust cause over-heat or, if accumulated to a certain extent, fouling of moving parts. In the early phase of product design, consider the following harmful effects of sand and dust exposure. This list is not intended to be all-inclusive. (Reference: MIL STD 810)

(a) Abrasion and erosion of surfaces.

(b) Penetration of seals.

(c) Degraded performance of electrical circuits.

(d) Obstruction/clogging of openings and filters.

(e) Physical interference with mating parts.

(f) Fouling/interference of moving parts.

(g) Reduction of heat transfer.

(h) Interference with optical characteristics.

(i) Overheating and fire hazard due to restricted ventilation or cooling.

(j) Wear (increased fretting due to imbedding between mating surfaces).

(k) Increased chaffing between non-mating contacting surfaces.

(l) Weight gain, static/dynamic balance.

(m) Attenuation of signal transmission.

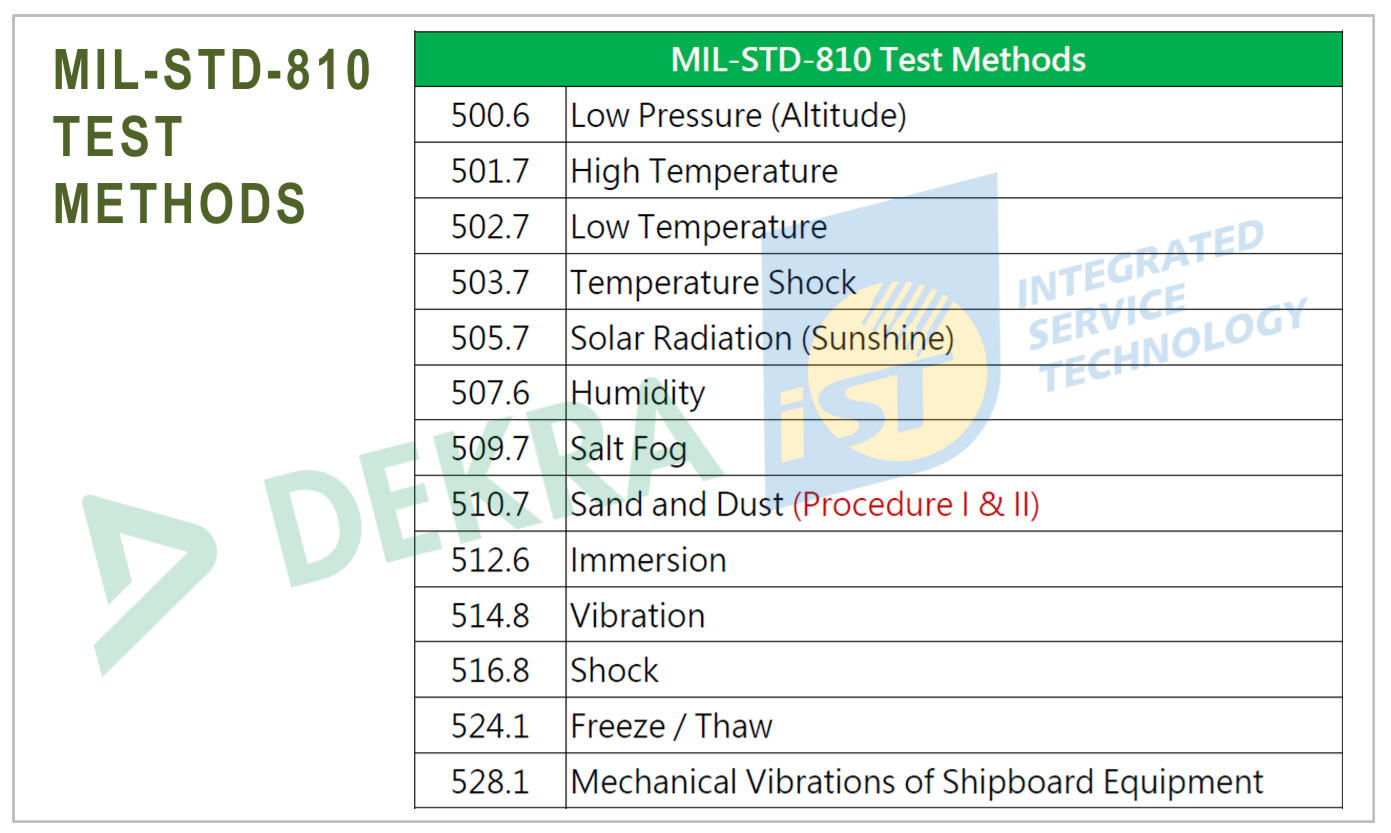

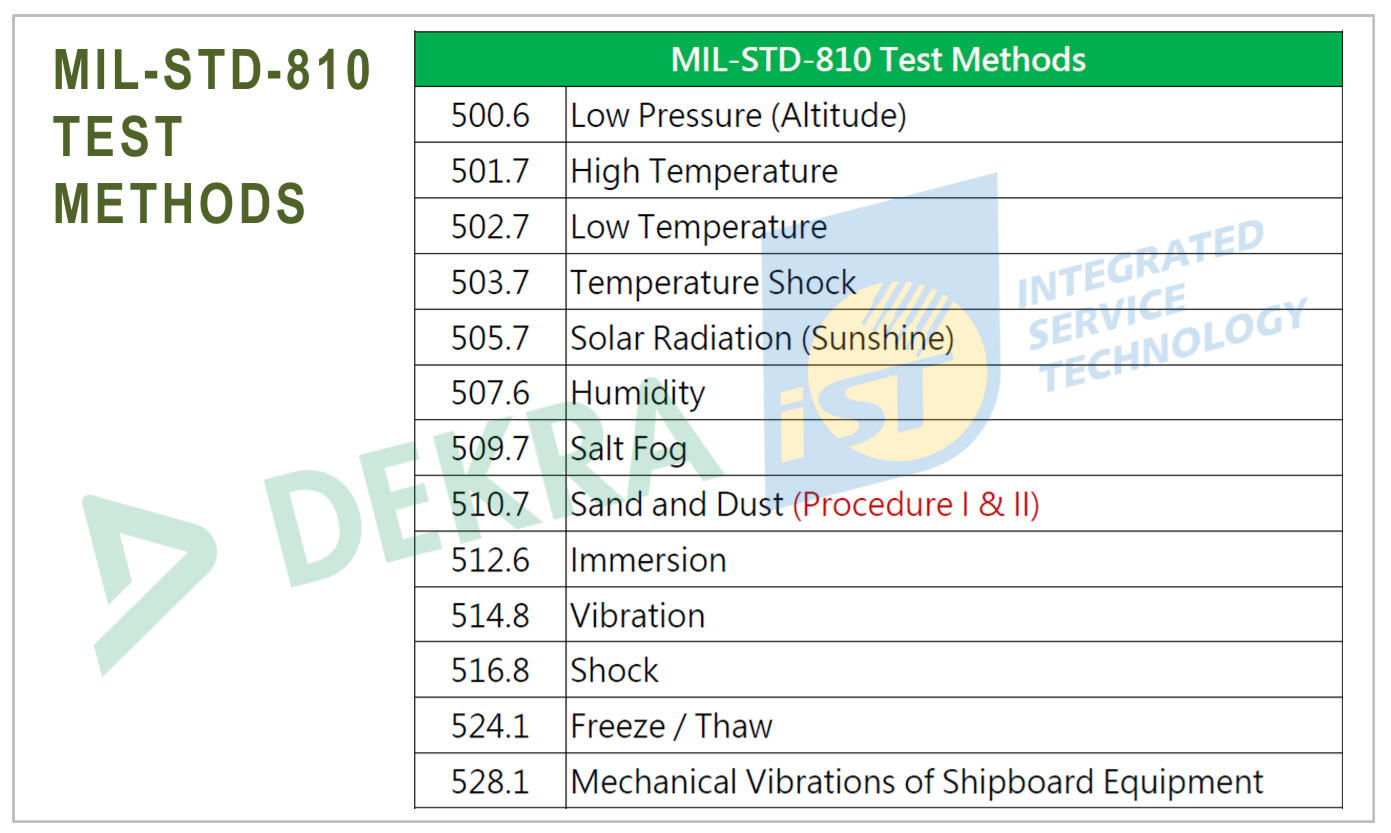

DEKRA iST offers one-stop validation services, consistently serving customers with comprehensive solutions and expanding the testing capacity at military level. Especially for the recognizably rugged products, upgrade of the testing capacity will further an outdoors-based platform for sand and dust testing with all-round features. The military-level test methods provided are described in Figure 5. Moreover, DEKRA iST can deliver a conformance report for customers to understand the types of severe testing conditions that their products have resistance to.

(a) Abrasion and erosion of surfaces.

(b) Penetration of seals.

(c) Degraded performance of electrical circuits.

(d) Obstruction/clogging of openings and filters.

(e) Physical interference with mating parts.

(f) Fouling/interference of moving parts.

(g) Reduction of heat transfer.

(h) Interference with optical characteristics.

(i) Overheating and fire hazard due to restricted ventilation or cooling.

(j) Wear (increased fretting due to imbedding between mating surfaces).

(k) Increased chaffing between non-mating contacting surfaces.

(l) Weight gain, static/dynamic balance.

(m) Attenuation of signal transmission.

DEKRA iST offers one-stop validation services, consistently serving customers with comprehensive solutions and expanding the testing capacity at military level. Especially for the recognizably rugged products, upgrade of the testing capacity will further an outdoors-based platform for sand and dust testing with all-round features. The military-level test methods provided are described in Figure 5. Moreover, DEKRA iST can deliver a conformance report for customers to understand the types of severe testing conditions that their products have resistance to.

Figure 5: Scope of Testing Items of MIL-STD-810 by DEKRA iST

Reference: DEKRA iST

Reference: DEKRA iST

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com